Description

Possible grades, structure, form and applications:

- Variable grades are available as per below table. (See Below Table 1)

- Full-Hard structure without being processed (without annealing)

- Batch Annealed & Continuous Annealed products are available,

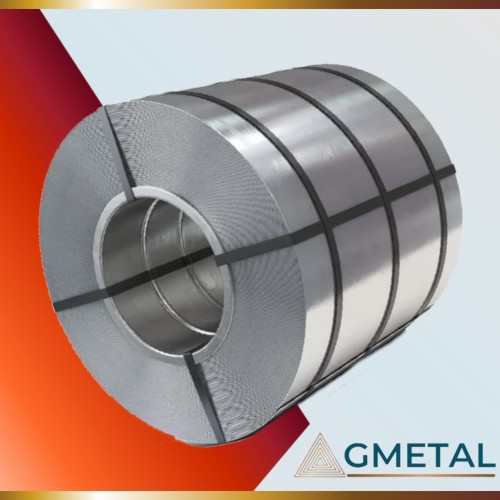

- Coils, slitted coils or cut to length,

- Trimmed (cut edge) or mill edge,

- Skin passed surface with different roughness ranges (See below Table 2)

- Different oiling amount (See Below Table 3)

- Special DOS A oiling is possible

| Table 2: Roughness ranges at skin passing: | |

| Bright | Ra ≤ 0.40 µm |

| Fine stone | Ra ≤ 0.90 µm |

| Normal / Matt | 0.6 μm < Ra ≤ 1.9 μm |

| Rough | Ra > 1,6 μm |

| Table 3: Possible Oiling Amounts | |

| Slight | 250…500 mg/m2 |

| Light | 500…1000 mg/m2 |

| Normal | 1000…2000 mg/m2 |

| Abundant | 1500…3000 mg/m2 |

| Other | Please specify |

Dimensions for Cold Rolled Coils:

Thickness: 0,25 mm – 3,00 mm (0.0098 inch – 0.1181 inch)

Width: max 1.530 mm (max 60,236 inch)

Coil Weight: Max 30 metric tons (66,138.678 lbs)

Coil ID: 508 mm / 610 mm (20 inch / 24 inch)

Dimensions for Cold Rolled Sheets:

Length: Max 12.000 mm (max 39.37 ft)

Thickness: 0,25 mm – 3,00 mm (0.0098 inch – 0.1181 inch)

Width: max 1.530 mm (max 60,236 inch)

Pallet weight: max 5,0 metric tons (max 11,023.11 lbs)

Dimensions for Cold Rolled Strips:

Width: max 1,530 mm (max 60,236 inch)

Thickness: 0,25 mm – 3,00 mm (0.0098 inch – 0.1181 inch)

Packing: max 10,0 metric tons (max 22,046.22 lbs)

Coil ID: 508 mm (20 inch)

| Flat Steel Products / Cold Rolled – Grade Index Application Areas and Correspondence of Cold Rolled Products |

||||||

| Main Properties & Application Areas | Standard | Grade | Previous | Europe | American | Japanese |

| General application steels for drawing (automotive, refrigerators, washing machines, home appliances, etc) |

JIS G 3141:2011 | SPCCT | ||||

| EN 10130:2006 | DC01 | St12 | ASTM A1008 CS Type B | JIS G3141 SPCC | ||

| EN 10130:2006 | DC03 | RRst13 | ASTM A1008 CS Type B | JIS G3141 SPCD | ||

| EN 10130:2006 | DC03 | RRst13 | ASTM A 1008 CS Type B | JIS G3141 SPCD | ||

| EN 10130:2006 | DC04 | St14 | ASTM A620 CD DDQAK | JIS G3141 SPCEN | ||

| EN 10130:2006 | DC05 | FeP05 | ASTM A1008 DDS | |||

| EN 10130:2006 | DC01 | St12 | ASTM A366 CR CQ | JIS G3141 SPCC | ||

| ASTM A1008-2015 | DS Type B | |||||

| TSG3100G | SPC270C | RRst13 | DC03 | ASTM A619 CR CQ | JIS G3141 SPCD | |

| TSG3100G | SPC270C | RRst13 | DC03 | ASTM A619 CR CQ | JIS G3141 SPCD | |

| General application steels for cold forming (Galvanizing, office equipment, lighting devices, etc.) | SAE J403-2014/ ASTM A1008-16 | 1006 / CS Type B | ASTM A1008 CS Type A | |||

| SAE J403-2014/ ASTM A1008-16 | 1008 /CS Type B | |||||

| SAE J403-2014 | 10B08 | |||||

| SAE J403-2014/ ASTM A1008-16 | 1010 / CS Type B | |||||

| SAE J403-2014 | 1012 | |||||

| SAE J403-2014 | 1018 Spec. | |||||

| Non-aging extra deep-drawing quality steels (Ultra low carbon IF steels) | EN 10130:2006 | DC04 | St14 | ASTM A1008 DS Type A | JIS G3141 SPCEN | |

| EN 10130:2006 | DC04 | |||||

| EN 10130:2006 | DC05 | FeP05 | ASTM A1008 DDS | |||

| EN 10130:2006 | DC06 | FeP06 | ASTM A1008 EDDS | |||

| TSG3100G | SPC270D | St14 | DC04 | ASTM A620 CR DDQAK | JIS G3141 SPCEN | |

| TSG3100G | SPC270D | St14 | DC04 | ASTM A620 CR DDQAK | JIS G3141 SPCEN | |

| Non-aging and extra deep-drawing steels suitable for manufacture of white goods | EN 10130:2006 | DC01 | St12 | ASTM A366 CR CQ | JIS G3141 SPCC | |

| EN 10130:2006 | DC03 | RRst13 | ASTM A619 CR DQ | JIS G3141 SPCD | ||

| Filter steel for automotive industry | EN 10130:2006 | DC04 | St14 | ASTM A620 CR DDQAK | JIS G3141 SPCEN | |

| Ultra deep-drawing and non-aging steels for automotive industry | EN 10130:2006 | DC04 | St14 | ASTM A1008 DS Type A | JIS G3141 SPCEN | |

| EN 10130:2006 | DC05 | FeP05 | ASTM A1008 DDS | |||

| EN 10130:2006 | DC06 | FeP06 | ASTM A1008 EDDS | |||

| Cold rolled steels for enamel coating | EN 10209:2013 | DC01EK | DIN 1623-3EK2 | |||

| EN 10209:2013 | DC01EK | DIN 1623-3EK2 | ||||

| EN 10209:2013 | DC04EK | DIN 1623-3EK4 | ASTM A424 Type 2 | |||

| EN 10209:2013 | DC04EK | DIN 1623-3EK4 | ASTM A424 Type-2 | |||

| EN 10209:2013 | DC05EK | |||||

| EN 10209:2013 | DC04ED | |||||

| EN 10209:2013 | DC04ED Mod | |||||

| EN 10209:2013 | DC06ED | FeD6 | ASTM A424 Type-3 | |||

| Cold rolled bake-hardening high yield strength steel for cold forming | EN 10268:2006+A1:2013 | HC220B | SEW 094 ZStE220 BH | |||

| EN 10268:2006+A1:2013 | HC260B | SEW 094 ZStE260 BH | ||||

| Cold rolled high yield strength steels for cold forming | EN 10268:2006+A1:2013 | HC220Y | SEW 094 ZStE220 P | ASTM A1008 BHS Gr.31 | ||

| EN 10268:2006+A1:2013 | HC260Y | SEW 094 ZStE260 P | ||||

| Cold rolled high yield strength dual-phase steel for cold forming | EN 10338:2015 | HCT490X | ||||

| EN 10338:2015 | HCT590X | |||||

| EN 10338:2015 | HCT 590X Mod | |||||

| High strength steels for cold forming | EN 10268:2006+A1:2013 | HC260 LA | SEW093 ZStE240 | ASTM A1008 SS Gr.33 | ||

| EN 10268:2006+A1:2013 | HC300 LA | SEW093 ZStE260 | ASTM A1008 SS Gr.40 | |||

| EN 10268:2006+A1:2013 | HC340 LA | SEW093 ZStE300 | ASTM A1008 HSLAS Gr.45 Class 2 | |||

| EN 10268:2006+A1:2013 | HC380 LA | SEW093 ZStE340 | ASTM A1008 HSLAS Gr.50 Class 2 | |||

| EN 10268:2006+A1:2013 | HC420 LA | SEW093 ZStE380 | ASTM A1008 HSLAS Gr.55 Class 2 | |||

| EN 10268:2006+A1:2013 | HC460 LA | |||||

| EN 10268:2006+A1:2013 | HC500 LA | |||||

| EN 10268:2006+A1:2013 | HC340LA (MOD.) | |||||

| EN 10268:2006+A1:2013 | HC460LA (MOD.) | |||||

| High strength Full-hard structural steels | SAE J403-2014 | 1030 | ||||

| SAE J403-2014 | 1040 | |||||

| SAE J403-2014 | 1045 | |||||

| Intermediate strength structural steel | 1623:2009 | S215G | St 37-3 G | ASTM A1008 SS Gr.33 Type 1 | ||

| Cold rolled steel for strap production | 1623:2009 | S215G | St 37-3 G | ASTM A1008 SS Gr.30 | ||

| Cold rolled, atmospheric corrosion resistant steels | JIS G 3125:2015 | SPA-C | ||||

| Cold rolled steels for tin coating | JIS G 3303:2017 | T-2,5 | TH260 | ASTM A623 T55 | ||

| JIS G 3303:2017 | T-3 | TH275 | ASTM A623 T57 | |||

| JIS G 3303:2017 | T-4 | TH415 | ASTM A623 T61 | |||

| Cold rolled carbon steel for strap production and structural applications | SAE J403-2014 | 1030 Mod | ||||